How to Create and Manage Repair Work Orders

To avoid revenue loss, products in compromised condition (e.g. in damaged packaging, with missing parts, etc.) can undergo various maintenance activities to improve their state. In Skustack, Repair Work Orders can be created for such products to initiate and track required restoration tasks within a chosen time frame. The Repair Work Orders can contain custom instructions and their associated costs.

Create Repair Work Orders through the Skustack Admin portal or use the Skustack application to add and oversee repair instructions and costs.

App

Manage Repair Work Orders

The Skustack application enables you to easily view the custom guidelines required to repair a unit.

To manage Repair Work Orders:

Navigate to the Work Order module and search for the desired Work Order.

Open the Repair Work Order and swipe it to the left to reveal shortcuts to other actions:

Bins – Tap the icon to see all bins where the product is stored (bins will show only if you’re logged into a bin-enabled warehouse).

Info – Tap to be directed to the Product Info module.

Tap on the Work Order to display products to be repaired. Tap on a product to view its list of Repair Instructions. The # of Repairs indicates the number of existing instructions.

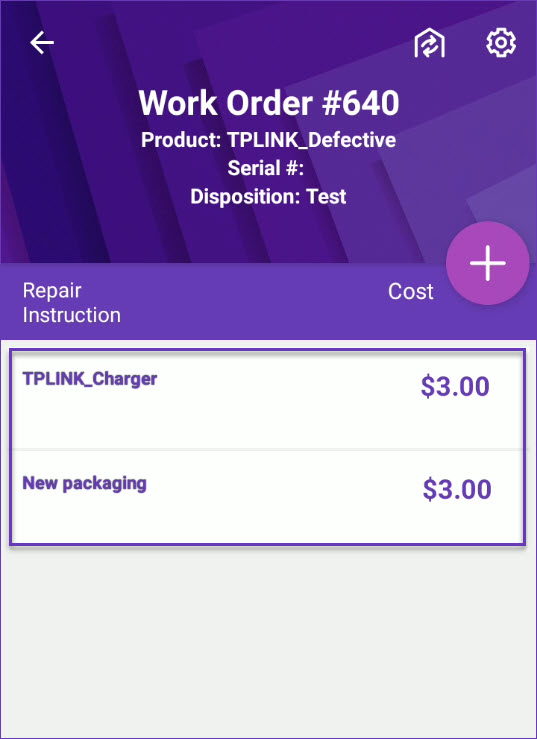

Repair Instructions

When you open the list of Repair Instructions, you’ll see the restoration tasks and their corresponding costs.

Add Repair Instructions

To add a new instruction and its cost to an existing Repair Work Order:

Tap the + icon.

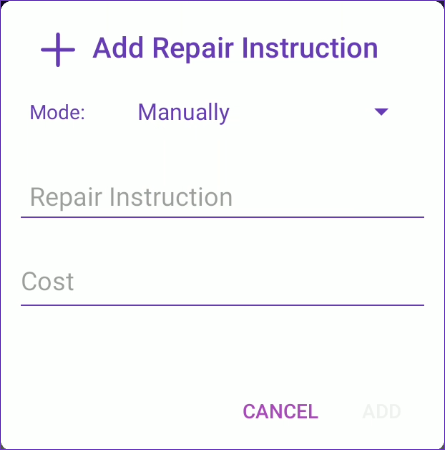

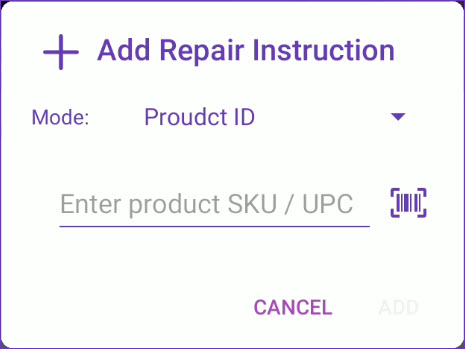

Choose a Mode to add the instruction:

Manually – Populate the Repair Instruction, its Cost.

ProductID – This mode gives you the option to enter/scan existing products that should be included in the repair (e.g. new charger, new lightbulb, etc.).

Tap Add. The new instruction will be visible in the repairs list.

Admin

Create Repair Work Orders

The Skustack Admin portal lets you easily create Repair Work Orders in two ways:

Via a standard Work Order of type Repair.

From graded units in Grading Work Orders.

To create a Repair Work Order:

Navigate to the Skustack Admin portal at https://xx.skustack.com (replace “xx” with your server ID or team name).

Enter your login credentials.

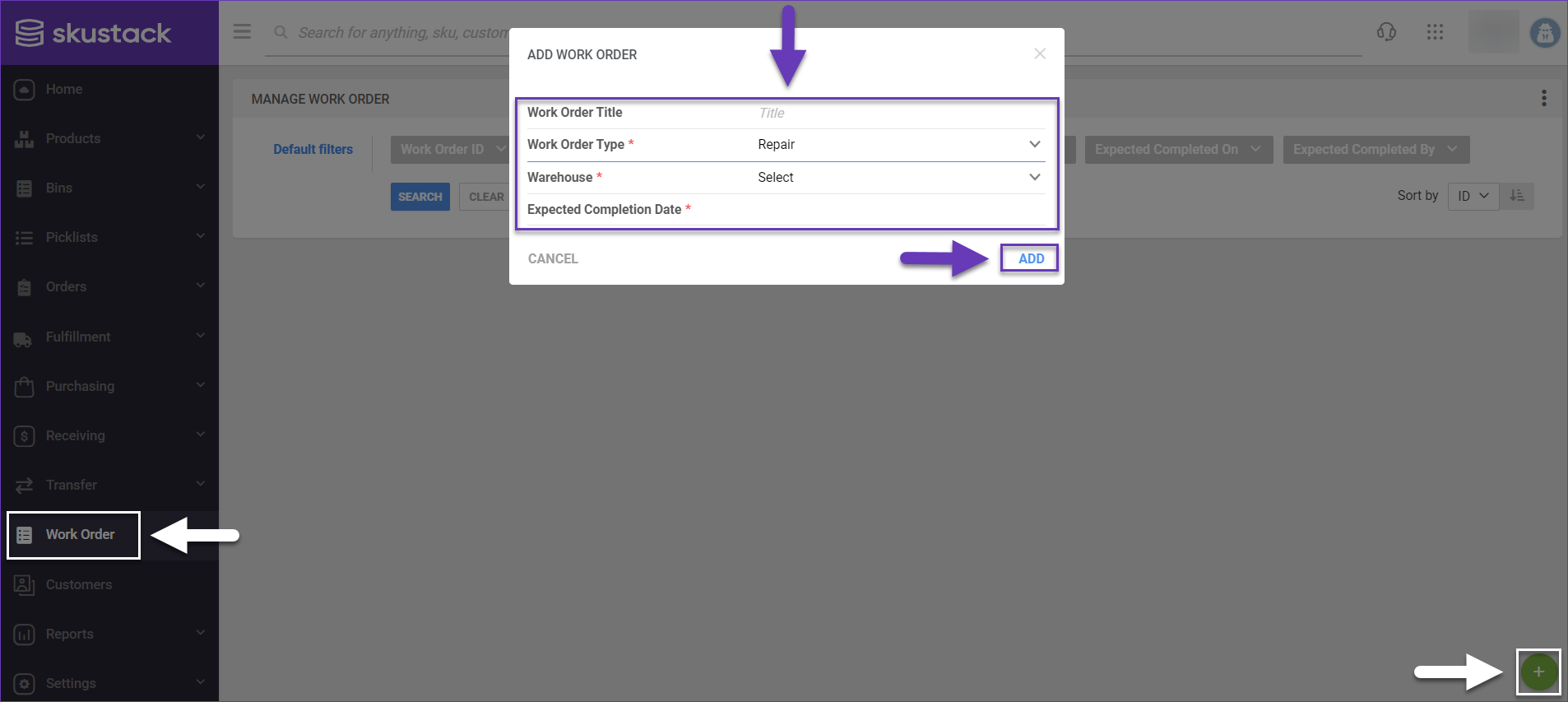

On the left, select Work Order and click on the green Plus icon.

Choose:

Word Order Title – A task name.

Work Order Type – Select Repair from the dropdown menu.

Warehouse – The affected warehouse.

Expected Completion Date – Estimated completion time.

Click Add and the work order will load on your screen, so you can Add Items to it.

Add Items

Next, proceed to add items to repair. You can do that either Individually or In bulk.

Individually

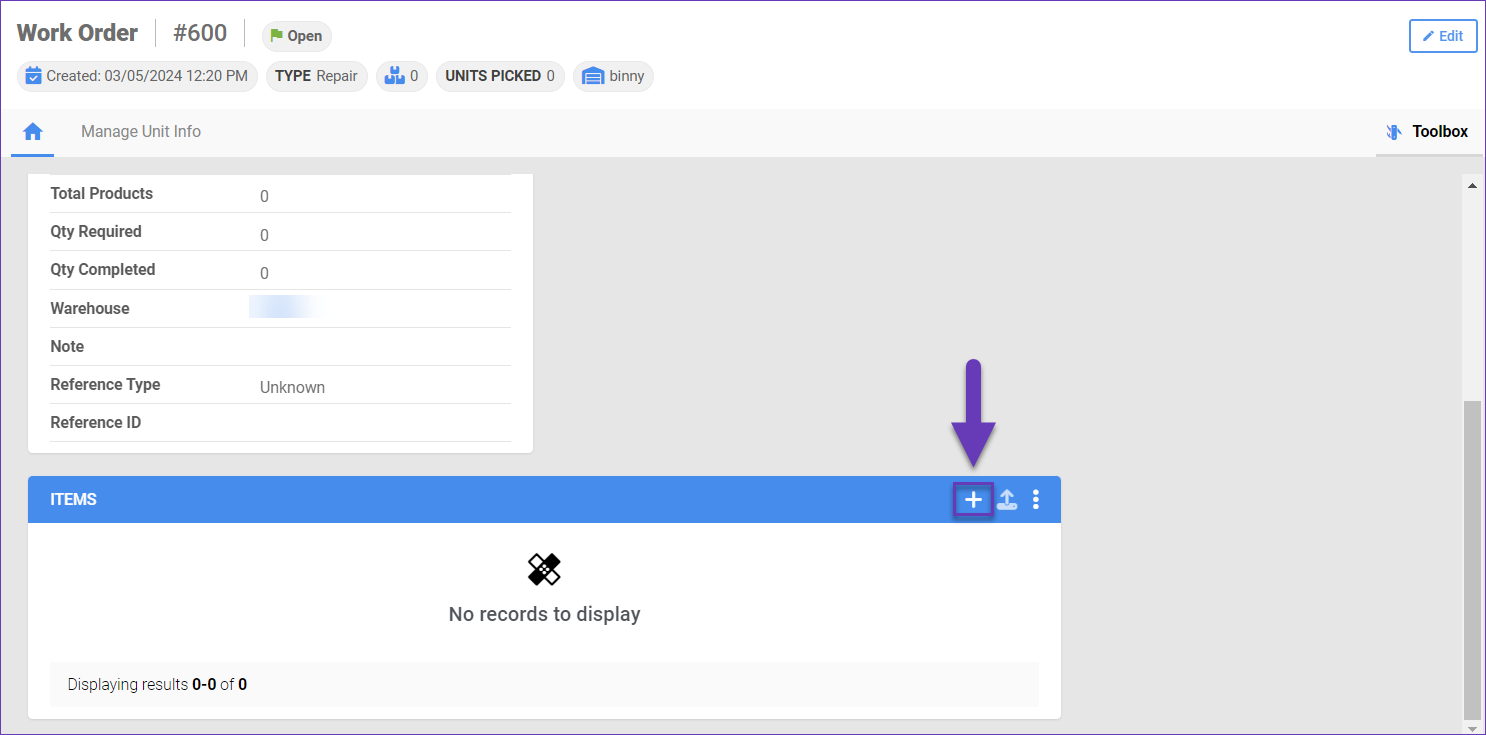

Navigate to the Items panel and click the + icon to add products.

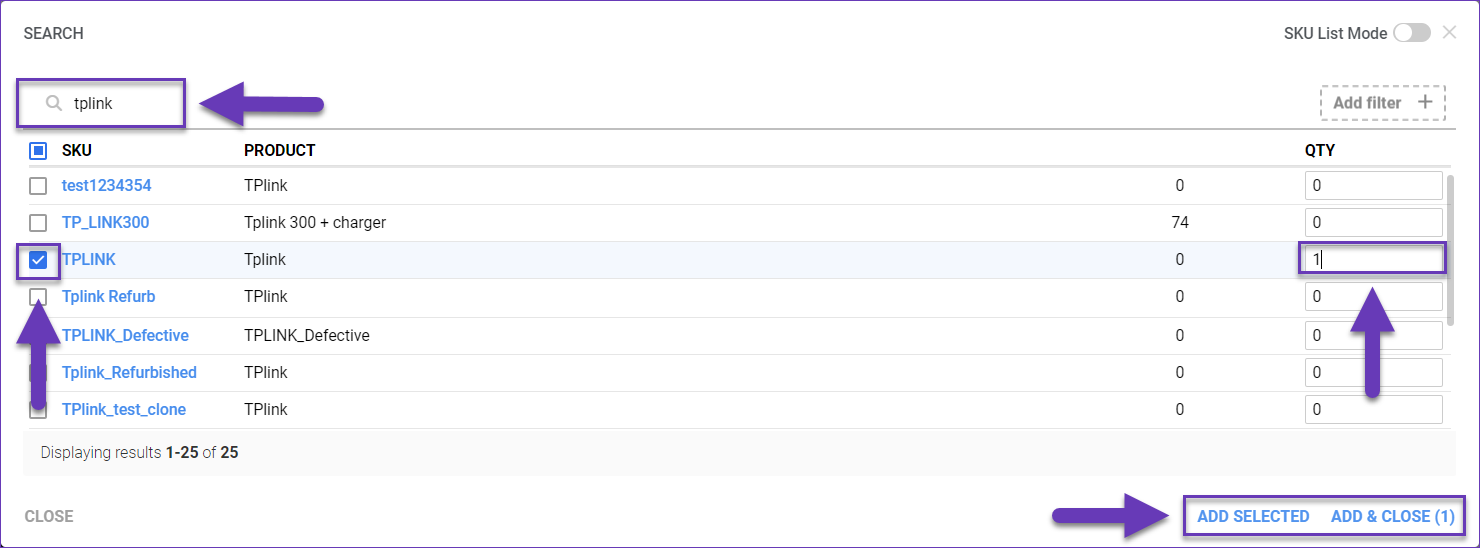

Search and select your desired products in the grid.

Enter the quantity for each item.

Click Add Selected to continue adding more products or Add & Close.

In Bulk

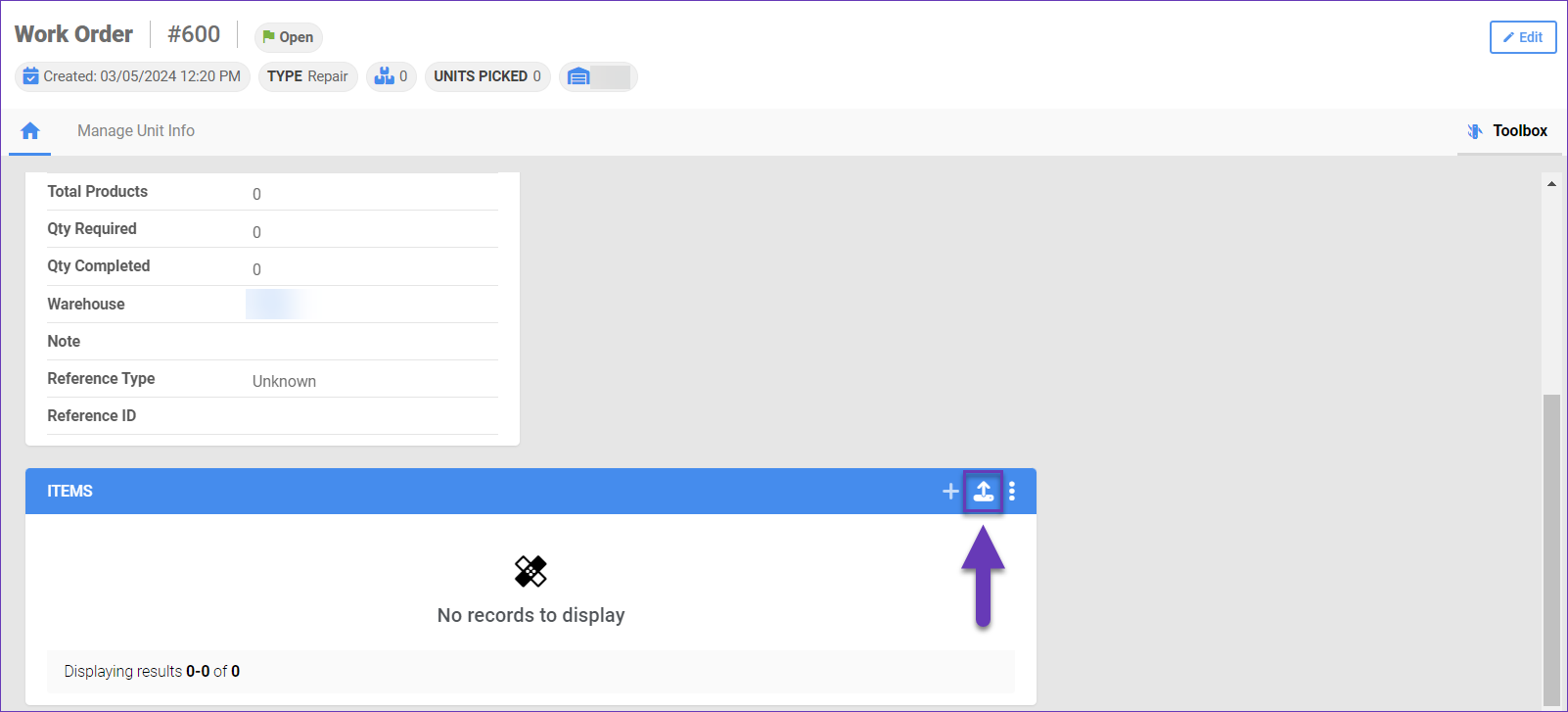

Navigate to the Items panel and click the Bulk Import icon.

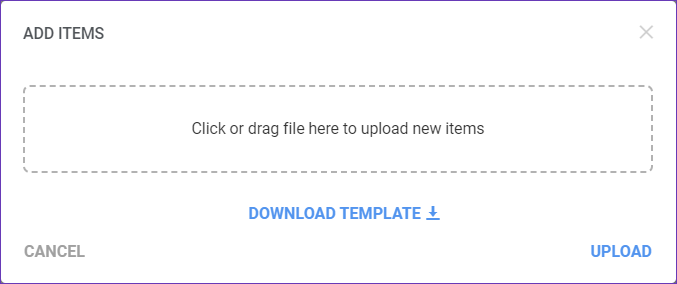

Click Download Template to generate a pre-populated file with all of the required columns.

Populate the required values (ProductID, WarehouseName, and TotalQtyRequired), save the file, and drag it back onto the grid.

Click Upload and the product/s will appear in the Items panel.

From Grading Work Order

When evaluated products in Grading Work Orders require repair activities, you may initiate them directly from the graded unit. To do so:

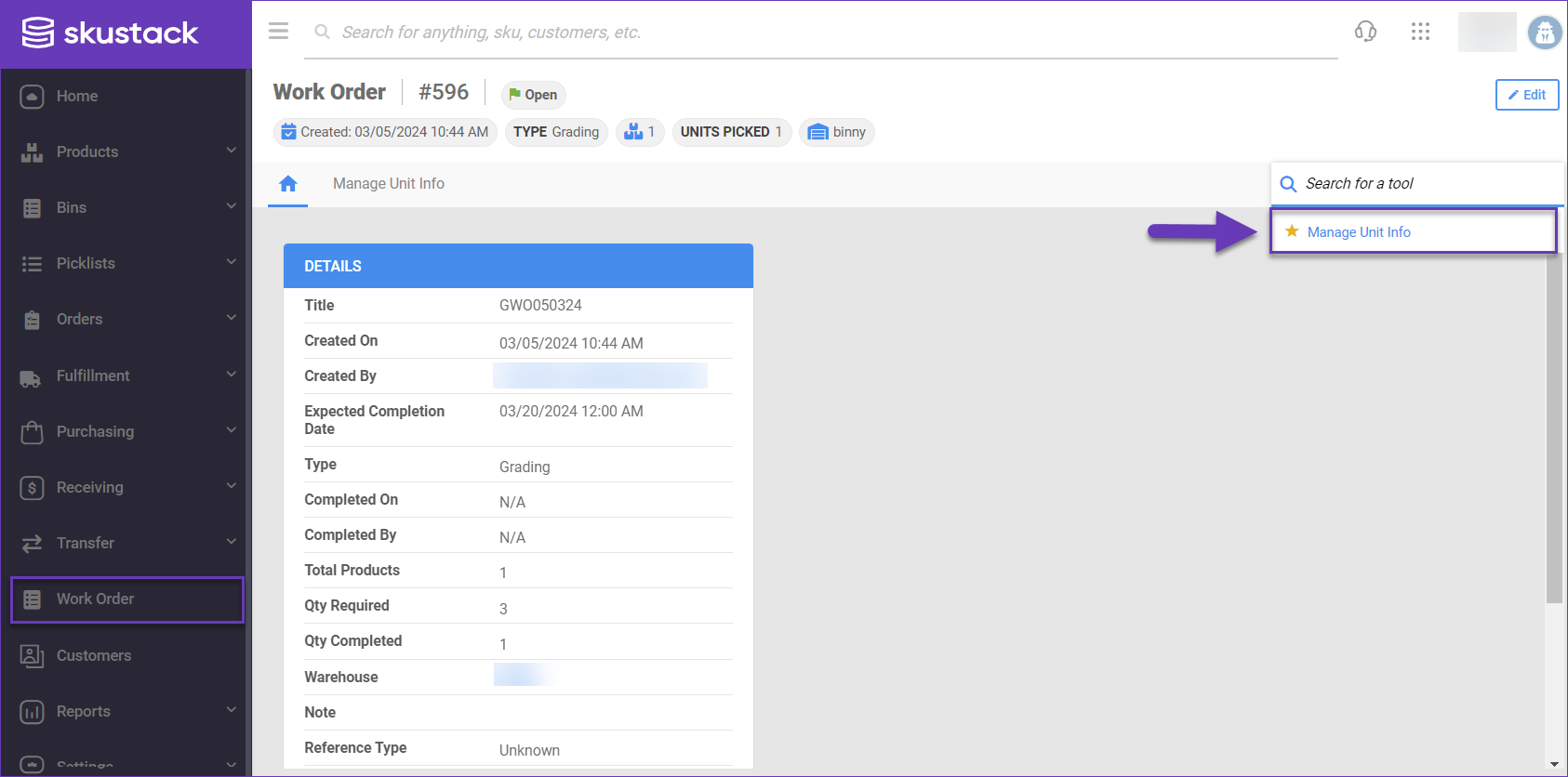

Open the required Grading Work Order.

From its Toolbox, select Manage Units.

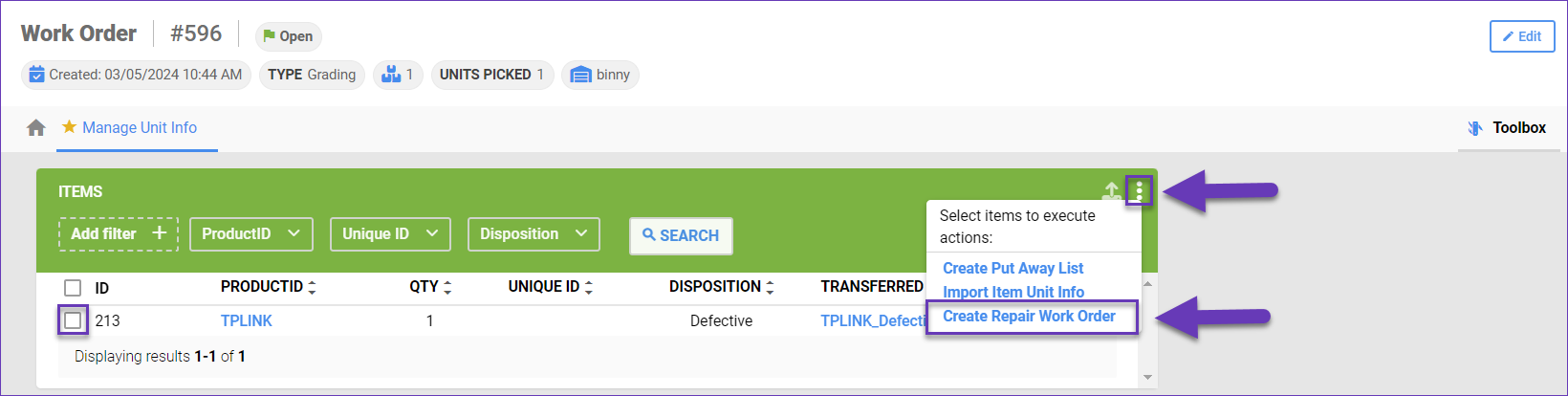

Choose which unit to repair, click on the three dots in the Items panel and select Create Repair Work Order.

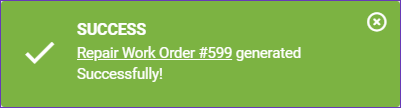

A success message with a link to the newly created work order will appear on your screen. The graded unit will be automatically added to the new Repair Work Order.

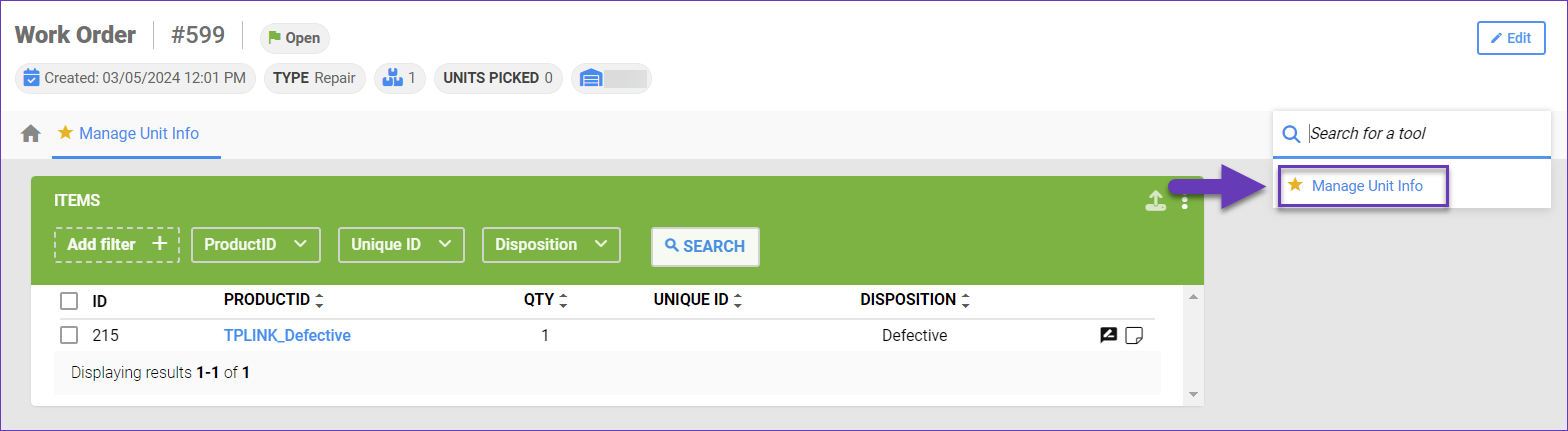

Manage Unit Info

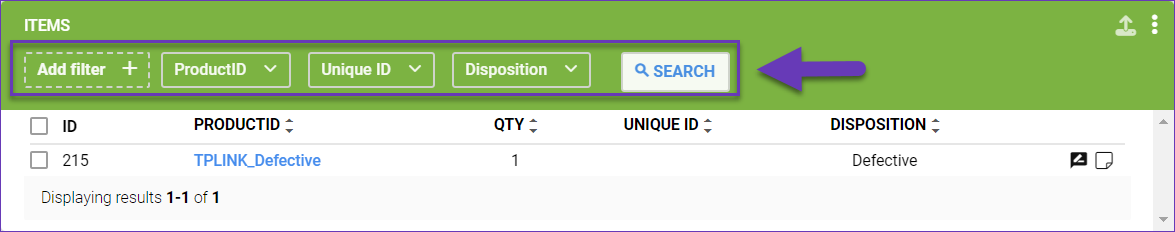

The product’s Repair instructions and respective costs are stored on the Repair Work Order’s Manage Unit Info page. To locate this information:

Navigate to the Work Order section and open the required order.

From the Toolbox, select Manage Unit Info.

Optionally, use the available filters in the Items panel to narrow the list of units.

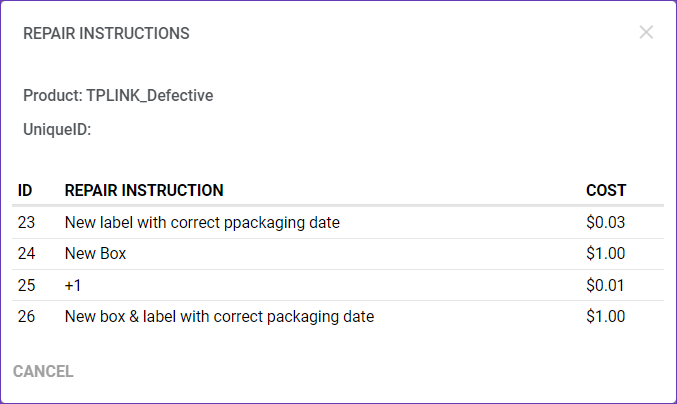

Repair Instructions

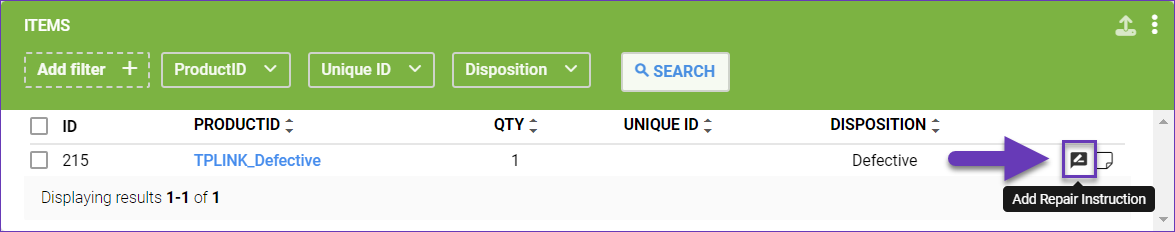

In the Items panel, next to the product’s disposition, you can add unit-specific Repair Instructions.

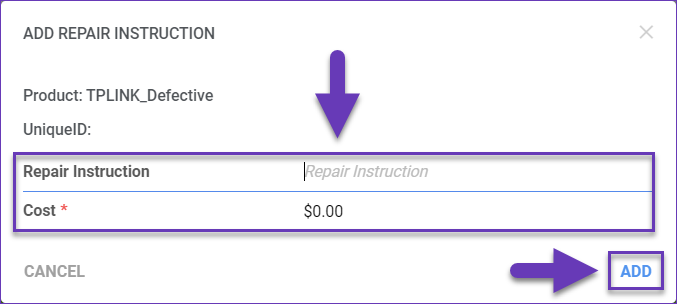

Populate the required repair steps and their respective cost and click Add.

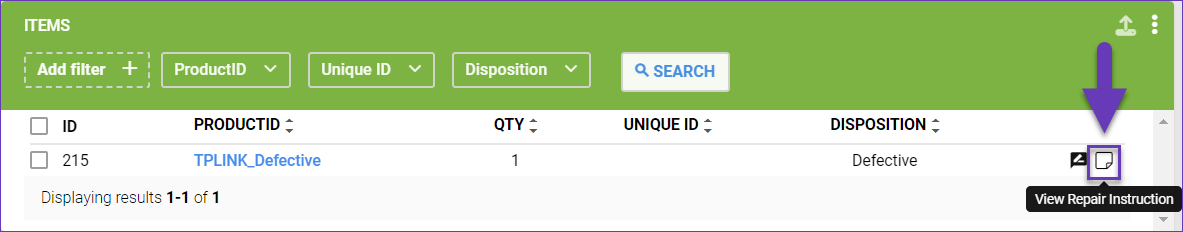

The new instruction can be displayed by clicking the View Instructions icon.

The list of Repair Instructions will appear.

Actions

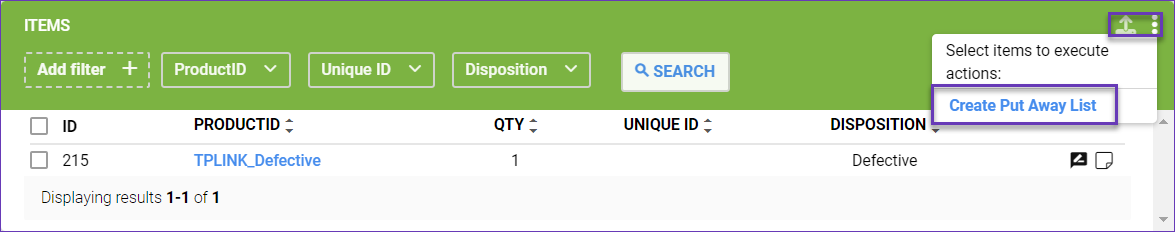

In the Items panel you can find the following Actions to manage your graded units:

Create a Put Away List – Select the required unit’s checkbox and use this action to create a Put Away List for it.

Import Item Unit Info – With this action you can update the unit grading information via a file import. Another file import option can be found next to the Action menu.

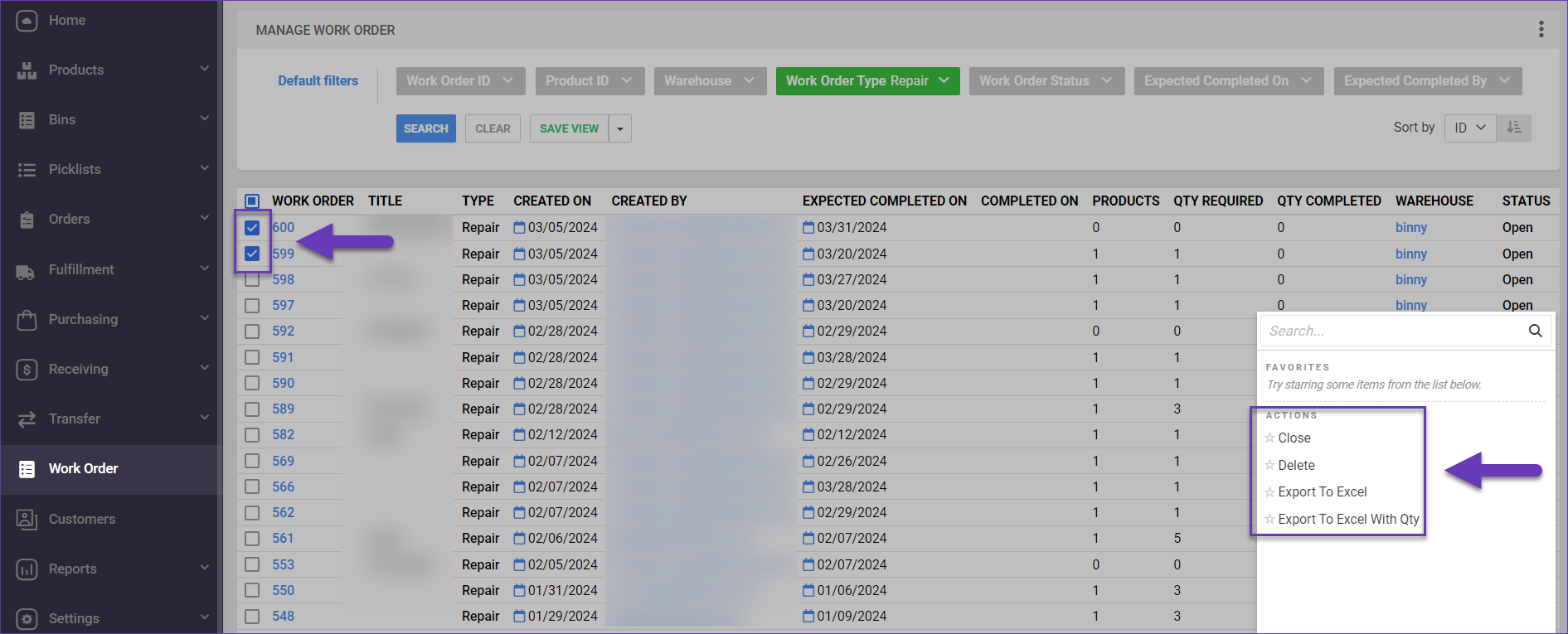

Manage Repair Work Orders

In addition to creating new work orders, you can utilize the Admin portal to:

Delete – Permanently delete existing repairs.

Close – Move work orders to a Closed status.

Export – Export an Excel sheet with basic Repairs information.

Export to Excel with Qty – Export an Excel sheet with Repairs information, including affected quantity

Simply check the desired work orders, click on the Action icon in the bottom-right corner and choose the required activity.

Related Settings

| SETTING | DESCRIPTION |

| Validate serial globally | Client setting. Enables serial number validation in Skustack. |

| Require Component Serial Scan If Necessary | Skustack’s Warehouse Management setting. When enabled, will force the user to scan serials for components that are set to require serial scan. |

| Allow Unlock Work Order | Skustack’s Warehouse Management setting. When enabled, this setting allows you to edit/add products to Work Orders. |

| Auto populate progress quantity when bin is selected | Skustack’s Warehouse Management setting. When a bin is selected, the Pick Qty field will automatically be set to the total quantity available in that bin, up to the quantity required. |

| Auto print new product labels | Skustack’s Warehouse Management setting. Automatically print out a label for new products after the transfer is complete. |